New MillTurn Machining Center Features Groundbreaking Design, Smart Software, and Intelligent Tools

At EMO 2021, WFL Millturn Technologies presented its new M20 MILLTURN complete machining center for the first time.

Alongside gear skiving technology, there is clear trend toward automation and the integration of sensors. The latest solutions from the Austrian company range from smart software to screw programming through to intelligent tools and clamping devices.

The aim when developing the M20 was to introduce a robust machine with the highest possible long-term accuracy. The machine frame is made from spheroidal graphite iron, ensuring optimal stability plus outstanding damping properties. This also means heavy roughing cuts can be made without compromise.

The most ground-breaking aspect, however, is the machine's new design.

The continuous toughened-glass front features an integrated performance data display and a touch panel for conveniently operating the tool magazine from the front of the machine. The working area is perfectly illuminated thanks to ultra-efficient and bright LED lights. A clearly visible LED strip at the bottom of the sliding door displays the machine status.

The M20 is available with a tailstock or counter spindle and features dynamic and powerful drives. The turning-boring-milling unit with integrated spindle motor and a B-axis with torque motor are entirely new features. The turning output of up to 44kW means even hard-to-machine materials can be handled with ease. The milling spindle with up to 25kW and 20,000rpm is ideally equipped for all machining tasks. In terms of the tool system, there is the option of using HSK 63 or Capto C6.

The individual tool holder with B-axis on the lower slide is a real highlight. The upper and lower system can be used simultaneously, and both systems are supplied by a reliable and dynamic tool changer from a shared magazine. This allows even complex components to be machined with optimal efficiency.

Fully Automated by intCELL

Another key benefit of the machine is the possibility of easily integrating a wide range of automation options. Depending on the customer's requirements, articulated robots, gantry loaders or an integrated production cell with the associated peripheral equipment can be implemented.

The newly integrated production cell "intCELL" is fitted on the right-hand side of the machine. The workpieces are supplied on a strip accumulator.

Furthermore, it is also possible to automatically switch the tool to the lower individual tool holder with B-axis. This makes it possible to set up the tools parallel to machining time and to automatically access the stock in the magazine. Stored tools can therefore be placed in the upper and lower tool holder. With the integrated loading concept, WFL has reduced the space requirement by 50% in comparison to a conventional production cell.

The M20's integrated loading feature is designed for chuck parts with a diameter of up to 300mm and a workpiece weight of 15kg. For shaft parts, a workpiece diameter of 100mm and a workpiece length of 300mm is possible.

Easy Screw Programming with ScrewCAM

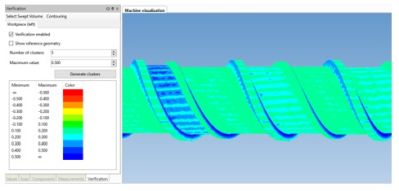

ScrewCAM is the latest and most innovative software for programming screws with complex geometries. The geometrical functions that can be manufactured include, among others, single or multi-threaded screws, variable depths, flexible pitch adjustment, wall shaping and wall incline.

In addition, the entire NC program will be checked for collisions and the correctness of the workpiece geometry produced, using a material removal simulation and geometrical verification against the 3D target geometry of the screw. The result is a verified NC program with estimated machining time.

Operational Data Acquisition with myWFL

The new operational data acquisition system is myWFL Cockpit.

Machine and program states will be displayed according to chronological order, productivity and technical availability. You can view this on a web browser via the control system, either on a PC or a mobile device. This means that the user can always be well-informed about their machine productivity.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy